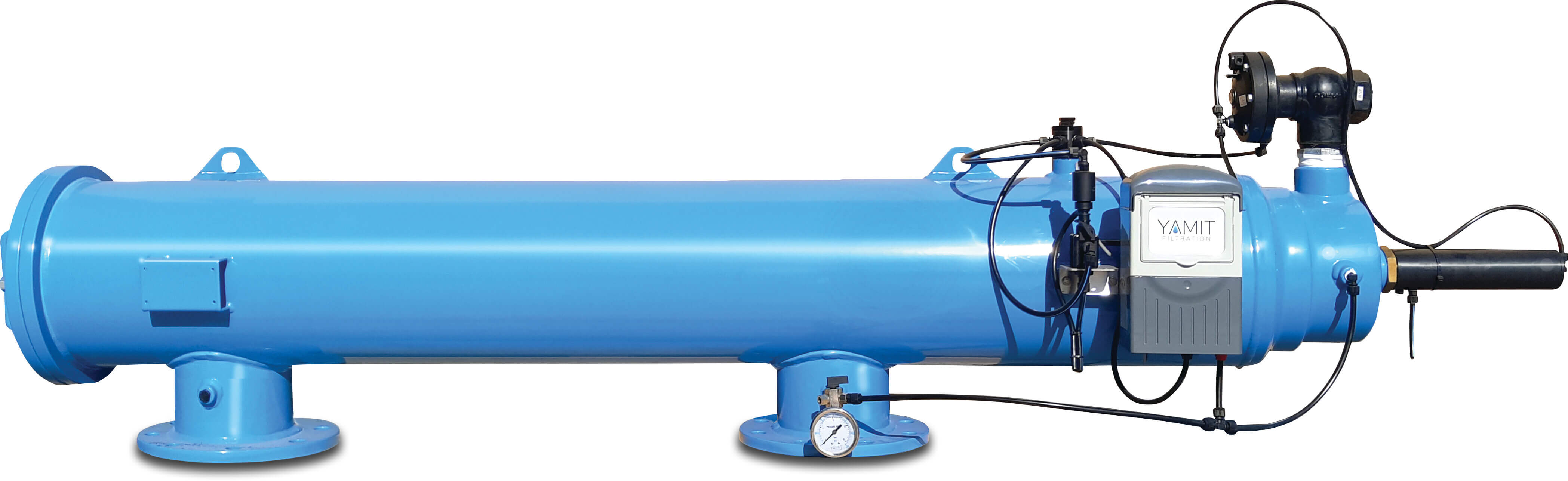

Yamit Automatic filter carbon steel ST37.2 epoxy coating DN150 flange 10bar 120micron stainless steel gauze 24VAC blue PN10 type AF806NX

Product number: 7027377

Manuals & drawings

All prices shown are gross prices. Please log in or contact sales for custom, discounted pricing.

Price excl. VAT

£7,542.77 / 1 pcs

£7,542.77 / pcs

Price incl. VAT

£9,051.32 / 1 pcs

£9,051.32 / pcs

Available at supplier, please contact us

- available on request, please contact sales team

Technical details

-

Pressure10 bar

-

Filtration120 micron

-

Surface treatmentepoxy coating

-

Connectionflange

-

Materialcarbon steel ST37.2

-

Voltage24VAC

-

Filter area8.41 m²

-

Colourblue

-

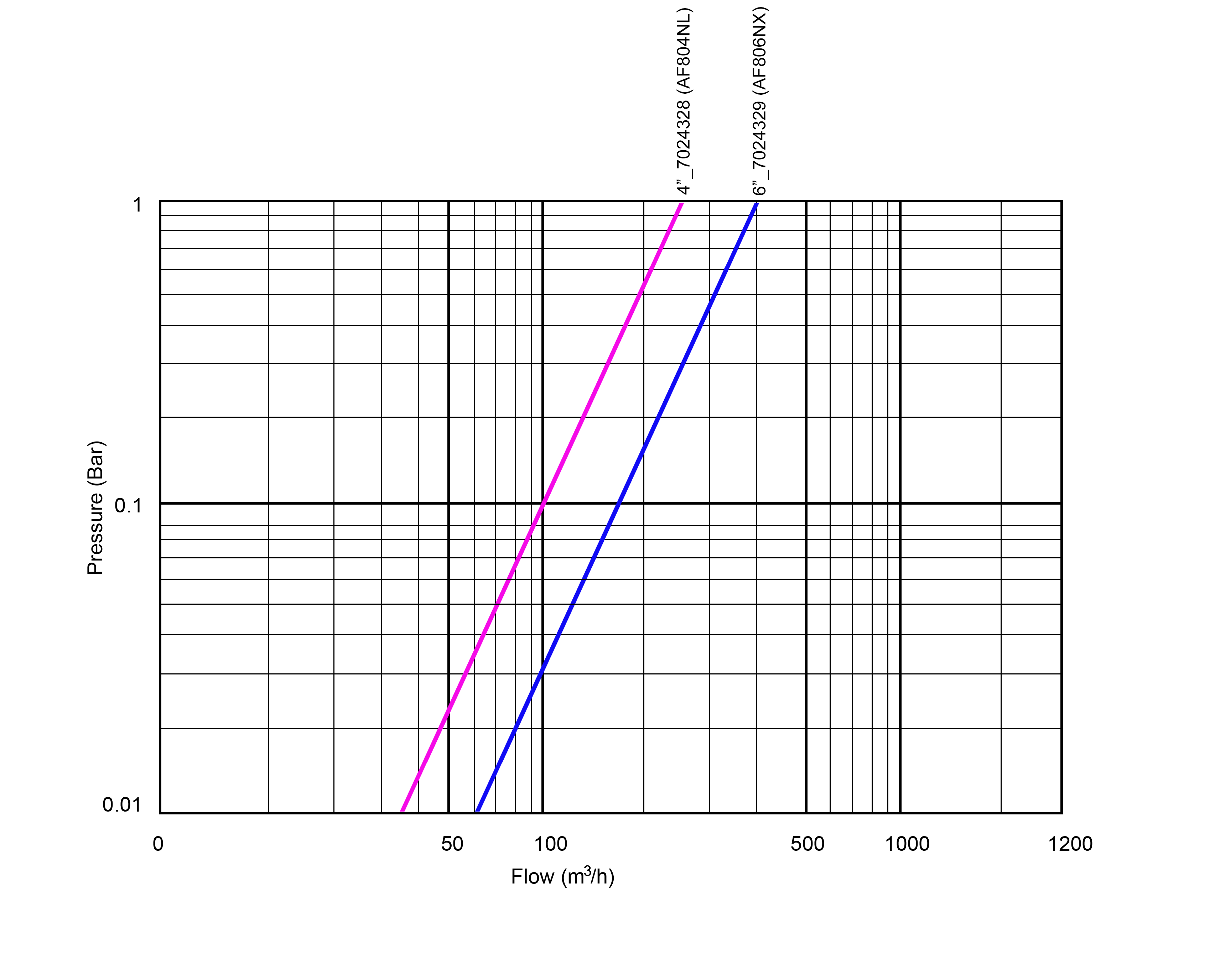

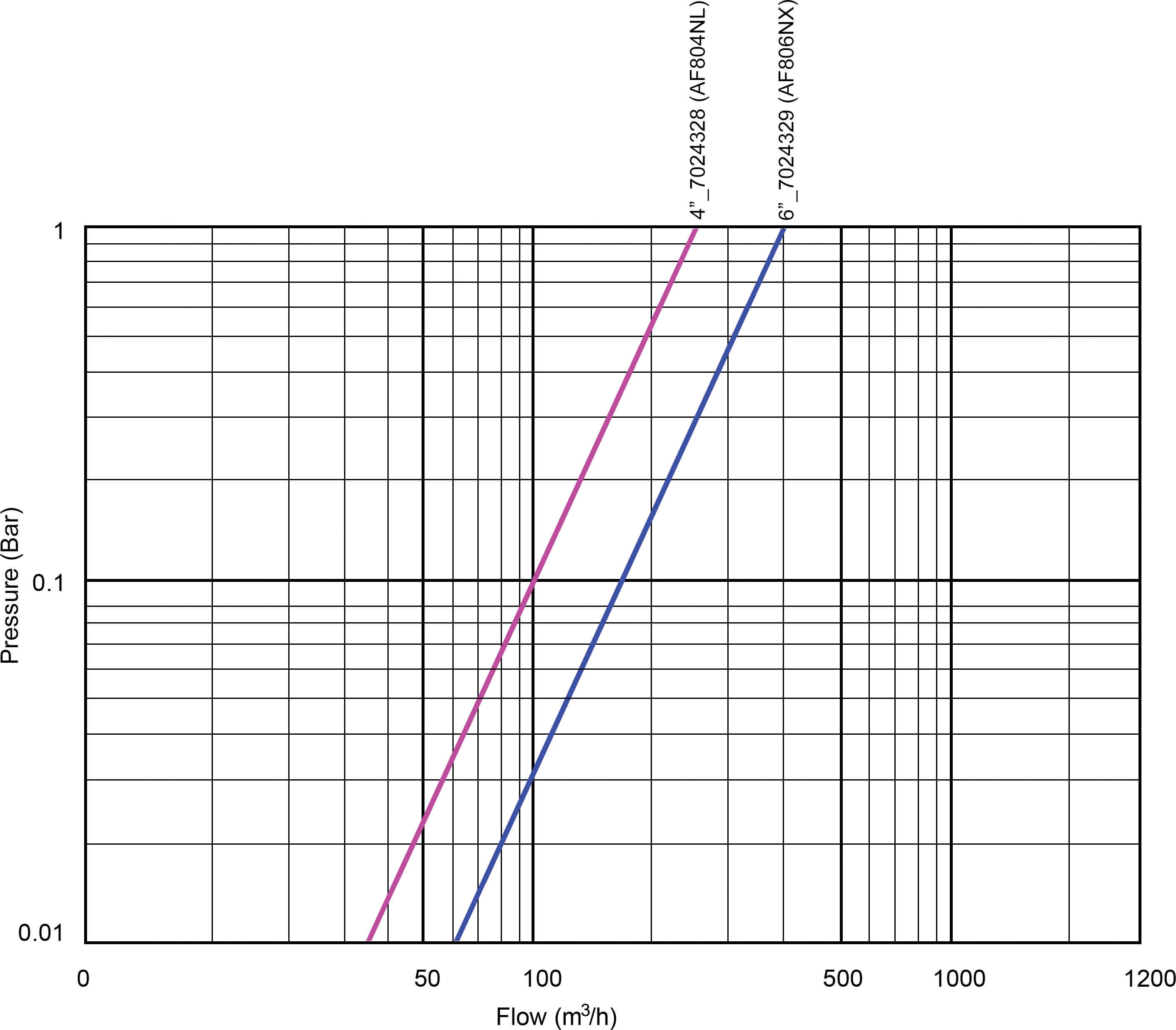

Backflush flow rate30 m³/h

-

Length2247 mm

-

Capacity160 m³/h

-

FlangePN10

-

Material filter elementstainless steel gauze

-

EAN4019305702775

-

Part number7027377

-

ManufacturerYamit

Product description

Available also in 100 micron screen. Please consult with us.

Equipped with an electronic control system 12V DC. For 24V AC or 6V DC please consult with us.

The filters are equipped with a coarse screen that protects the finer screen from stones and larger particles. The coarse screen can be cleaned manually periodically.

Operation: cleaning of the screen is performed automatically once the pressure loss (ΔP) across the filter has reached the preset value up to 0.5 bar.

Minimum operating workign presure during flushing: 2 bar.

Flushing: The flushing cycle takes 5 seconds. The flushing valve closes at the end of the cycle, pressure reapplied to the piston, moving the nozzles back to their rest position, and the filter is cleaned. During the whole process water supply is uninterrupted.

Applications: primary filter installed at the main control head.

Equipped with an electronic control system 12V DC. For 24V AC or 6V DC please consult with us.

The filters are equipped with a coarse screen that protects the finer screen from stones and larger particles. The coarse screen can be cleaned manually periodically.

Operation: cleaning of the screen is performed automatically once the pressure loss (ΔP) across the filter has reached the preset value up to 0.5 bar.

Minimum operating workign presure during flushing: 2 bar.

Flushing: The flushing cycle takes 5 seconds. The flushing valve closes at the end of the cycle, pressure reapplied to the piston, moving the nozzles back to their rest position, and the filter is cleaned. During the whole process water supply is uninterrupted.

Applications: primary filter installed at the main control head.